A non-volatile memory technology based on carbon nanotubes that is poised for commercialisation in 2018 is expected to be more disruptive to enterprise storage, servers, and consumer electronics than Flash memory, according to a new report from BCC Research.

“It is rare to see a technology catch fire after so long in development, but NRAM appears poised to do just that,” said BCC research editorial director Kevin Fitzgerald. “In fact, your next smartphone could be a carbon-based lifeform.”

The BCC report predicts the overall Nano RAM (NRAM) market will see a compound annual growth rate of 62.5% between 2018 and 2023, with the embedded systems market in which it will be used expected to grow from $4.7 million (€4.4 million) in 2018 to $217.6 million (€204 million) in 2023. That would represent a combined annual growth rate over those five years of 115.3%.

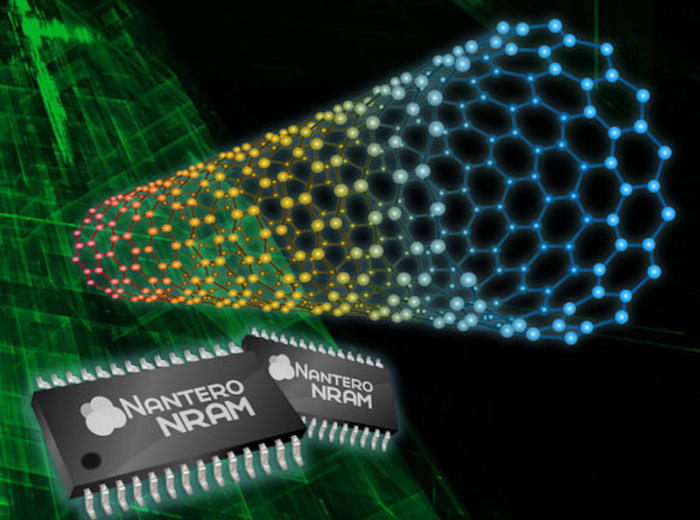

Invented in 2001 by Woburn, Mass.-based Nantero, NRAM is claimed to have 1,000 times the performance of DRAM but stores data like NAND Flash memory; when the power is turned off, the data remains.

New technologies

RAM is up against an abundant field of new memory technologies that are expected to challenge NAND Flash in speed, endurance and capacity, according to Jim Handy, principal analyst with semiconductor research firm Objective Analysis.

For example, Ferroelectric RAM (FRAM) has already shipped in high volume; IBM has developed Racetrack Memory; Intel, IBM and Numonyx have all produced Phase-Change Memory (PCM); Magnetoresistive Random-Access Memory (MRAM) has been under development since the 1990s; Hewlett-Packard and Hynix have been developing ReRAM, also called Memristor; and Infineon Technologies has been working on Conductive-Bridging RAM (CBRAM).

“These guys are in for a battle of holy war proportions,” BCC Research’s senior editor and report co-author Chris Spivey said via e-mail. “Each of these memories can be used in many different ways – and so they will compete (eventually) across the board. And so as battles end only one will likely remain extant.”

Carbon-based move

In a published question and answer sessions, Spivey said the most exciting aspect of NRAM is the movement from silicon to carbon-based memory, “which can evidently be carried out seamlessly on traditional CMOS foundries and also, it seems, even in logic foundries. This ushers in an era of potential mass customisation.”

BCC Research agrees that NRAM has the potential for mass customisation, meaning a chip can be optimised for many specific tasks. That will enable things like cheap, abundant autonomous IoT sensors as well as memory for the smartphone industry, embedded ASICS for automobiles and even headphones that store music intrinsically.

“It has had a long history of high hopes that went undelivered till now,” BCC Research said. “However, this report reveals to the public for the first time actual chip architecture. Coupled to licensing announcements anticipated (early) in the first quarter of 2017, the tide will turn precipitously.”

Catching on

Over the past 16 years, NRAM has sputtered as it has attempted to catch on as a new memory technology. As early as 2003, for example, industry pundits were predicting it would challenge the memory market. In 2005, Nantero itself pronounced NRAM as a “universal memory” that would be in production the next year; the memory, however, remained in the engineering phase through 2009.

BCC Research described NRAM’s lengthy path to market as “a classic David versus Goliath adventure… only now David has successfully enlisted the help of one of Goliath’s cousins, Fujitsu.”

In August, Fujistu Semiconductor Ltd. became the first manufacturer to announce it is mass producing the NRAM.

Fujitsu plans to develop a custom embedded storage-class memory module using the DDR4 interface by the end of 2018, with the goal of expanding the product line-up into a stand-alone NRAM product family from Fujitsu’s foundry, Mie Fujitsu Semiconductor Ltd; the stand-alone memory module will be sold through resellers, who’ll rebrand it.

2 x NAND Flash

Using the DDR4 specification interface, NRAM could sport up to 3.2 billion data transfers per second or 2.4Gb/s – more than twice as fast as NAND flash. Natively, however, the NRAM’s read/write capability is thousands of times faster than NAND Flash, Greg Schmergel, CEO of Nantero, said. The bottleneck, therefore, is the computer BUS interface.

“Nanotube switch [states] in picoseconds – going off to on and on to off,” Schmergal said in an earlier interview with Computerworld. A picosecond is one trillionth of a second.

Nanotube strength

Carbon nanotubes are strong – very strong. In fact, they are 50 times stronger than steel, and they’re only 1/50,000th the size a human hair. Because of carbon nanotubes’ strength, NRAM has far greater write endurance compared to NAND flash.

The best NAND flash, with error correction code, can withstand about 100,000 erase-write cycles. According to Nantero, NRAM can withstand 1012 write cycles and 1015 read cycles – an almost infinite number.

NRAM is made up of an interlocking fabric matrix of carbon nanotubes that can either be touching or slightly separated. Each NRAM “cell” or transistor comprises the network of the carbon nanotubes that exist between two metal electrodes. The memory acts the same way as other resistive non-volatile RAM technologies.

Subscribers 0

Fans 0

Followers 0

Followers